Hydraulic pile hammer is also called hydraulic pile hammer, pile driver hydraulic hammer, hydraulic impact hammer, etc. It is a new generation of electromechanical-hydraulic integrated multi-functional hammering equipment developed by using a number of innovative technologies. It has outstanding advantages such as adjustable impact strength, high pile driving efficiency, not easy to damage piles, convenient shifting and transition, more safety and environmental protection, etc. It has become a substitute for high-polluting diesel hammers and low-efficiency static pile drivers. If you need it, welcome to call consult.

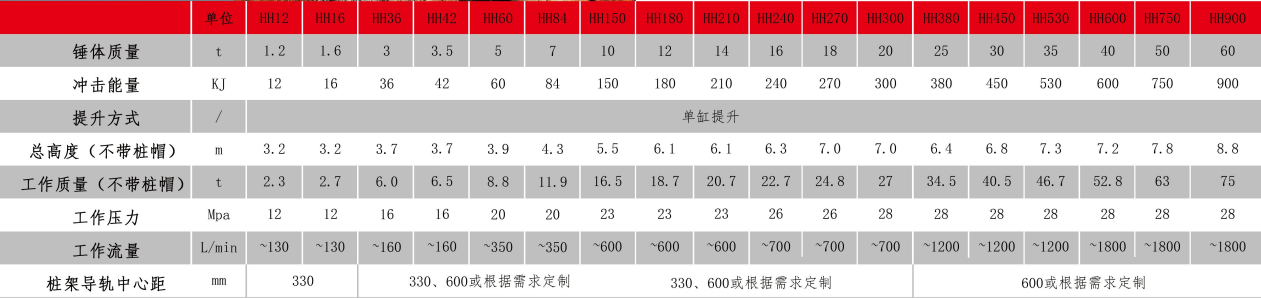

Hydraulic piling hammer model

1. HH12 hydraulic pile hammer, hammer mass 1.2t, impact energy 12KJ, lifting method is single cylinder lifting, total height 3.2m, working mass 2.3t, working pressure 12Mpa, working flow ~130L/min, center distance of pile guide rail 330mm;

2. HH16 hydraulic pile hammer, hammer mass 1.6t, impact energy 16KJ, lifting method is single cylinder lifting, total height 3.2m, working mass 2.7t, working pressure 12Mpa, working flow ~130L/min, center distance of pile guide rail 330mm;

3.HH36 hydraulic piling hammer, hammer mass 3t, impact energy 36KJ, lifting method is single cylinder lifting, total height 3.7m, working mass 6.0t, working pressure 16Mpa, working flow ~160L/min, center distance of pile guide rail 330 , 600mm or customized according to demand;

4.HH42 hydraulic pile hammer, hammer mass 3.5t, impact energy 42KJ, lifting method is single cylinder lifting, total height 3.7m, working mass 6.5t, working pressure 16Mpa, working flow ~160L/min, center distance of pile guide rail 330, 600mm or customized according to demand;

5.HH60 hydraulic piling hammer, the weight of the hammer body is 5t, the impact energy is 60KJ, the lifting method is single-cylinder lifting, the total height is 3.9m, the working mass is 8.8t, the working pressure is 20Mpa, the working flow is ~350L/min, and the center distance of the pile guide rail is 330 , 600mm or customized according to demand;

6. HH84 hydraulic pile hammer, hammer mass 7t, impact energy 84KJ, lifting method is single cylinder lifting, total height 4.3m, working mass 11.9t, working pressure 20Mpa, working flow ~350L/min, center distance of pile guide rail 330 , 600mm or customized according to demand;

7. HH150 hydraulic piling hammer, hammer body mass 10t, impact energy 150KJ, lifting method is single cylinder lifting, total height 5.5m, working mass 16.5t, working pressure 23Mpa, working flow ~600L/min, pile frame guide center distance 330 , 600mm or customized according to demand;

8. HH180 hydraulic pile hammer, hammer mass 12t, impact energy 180KJ, lifting method is single cylinder lifting, total height 6.1m, working mass 18.7t, working pressure 23Mpa, working flow ~600L/min, center distance of pile frame guide rail 330 , 600mm or customized according to demand;

9. HH210 hydraulic pile hammer, hammer body mass 14t, impact energy 210KJ, lifting method is single cylinder lifting, total height 6.1m, working mass 20.7t, working pressure 23Mpa, working flow ~600L/min, center distance of pile guide rail 330 , 600mm or customized according to demand;

10.HH240 hydraulic pile hammer, hammer body mass 16, impact energy 240KJ, lifting method is single cylinder lifting, total height 6.3m, working mass 22.7t, working pressure 26Mpa, working flow ~700L/min, center distance of pile guide rail 330 , 600mm or customized according to demand;

11.HH270 hydraulic piling hammer, the weight of the hammer body is 18t, the impact energy is 270KJ, the lifting method is single-cylinder lifting, the total height is 7.0m, the working mass is 24.8t, the working pressure is 26Mpa, the working flow is ~700L/min, and the center distance of the pile guide rail is 330 , 600mm or customized according to demand;

12.HH300 hydraulic piling hammer, hammer mass 20t, impact energy 300KJ, lifting method is single cylinder lifting, total height 7.0m, working mass 27t, working pressure 28Mpa, working flow ~700L/min, center distance of pile frame guide rail 330, 600mm or customized according to demand;

13.HH380 hydraulic pile hammer, hammer weight 25t, impact energy 380KJ, lifting method is single cylinder lifting, total height 6.4m, working mass 34.5t, working pressure 28Mpa, working flow ~1200L/min, center distance of pile guide rail 600mm Or customized according to demand;

14.HH450 hydraulic piling hammer, hammer weight 30t, impact energy 450KJ, lifting method is single cylinder lifting, total height 6.8m, working mass 40.5t, working pressure 28Mpa, working flow ~1200L/min, center distance of pile guide rail 600mm Or customized according to demand;

15.HH530 hydraulic pile hammer, hammer weight 35t, impact energy 530KJ, lifting method is single cylinder lifting, total height 7.3m, working mass 46.7t, working pressure 28Mpa, working flow ~1200L/min, pile frame guide center distance 600mm Or customized according to demand;

16.HH600 hydraulic piling hammer, hammer mass 40t, impact energy 600KJ, lifting method is single cylinder lifting, total height 7.2m, working mass 52.8t, working pressure 28Mpa, working flow ~1800L/min, center distance of pile guide rail 600mm Or customized according to demand;

17.HH750 hydraulic pile hammer, the weight of the hammer body is 50t, the impact energy is 750KJ, the lifting method is single-cylinder lifting, the total height is 7.8m, the working mass is 63t, the working pressure is 28Mpa, the working flow is ~1800L/min, the center distance of the pile frame guide is 600mm or Customized according to needs;

18.HH900 hydraulic pile hammer, hammer body mass 60t, impact energy 900KJ, lifting method is single cylinder lifting, total height 8.8m, working mass 75t, working pressure 28Mpa, working flow ~1800L/min, pile frame guide center distance 600mm or Customized according to needs.

The working principle of hydraulic pile hammer

The hydraulic pile hammer belongs to the impact pile hammer, which can be divided into single-acting type and double-acting type according to its structure and working principle. The so-called single-acting type means that the impact hammer core is quickly released to a predetermined height by a hydraulic device, and the impact hammer core falls freely; double-acting type means that the impact hammer core is lifted to a predetermined height by a hydraulic device, and the acceleration energy is obtained from the hydraulic system to increase the impact speed. , piling. This also corresponds to the two pile theories. The single-acting hydraulic pile hammer corresponds to the light weight theory. It has the characteristics of large hammer core weight, low impact speed, and long hammer time. material, the pile damage rate is low, especially suitable for concrete pipe piles. The double-acting hydraulic piling hammer corresponds to the light hammer weight theory. It has the characteristics of low hammer core weight, high impact speed, short pile hammering time, high impact energy, and is most suitable for steel piles.

Hydraulic hammer pile driver. It is a new type of pile driver, which is powered by oil pressure, and can adjust the hydraulic pressure according to the quality of the stratum soil to achieve the appropriate impact force. Small and medium hydraulic pile drivers are often used in highway guardrail piling and highway guardrail construction. Similar piling equipment includes: hydraulic piling machine, road piling machine, guardrail piling machine, road drilling machine. Compared with diesel pile drivers, the energy transfer efficiency of hydraulic hammer pile drivers can reach 70% to 95%, while the energy transfer efficiency of diesel hammer pile drivers is only 20% to 30%. Hydraulic hammer pile driver has precise piling control ability, which can realize piling operation in different strata; hydraulic hammer pile driver has excellent performance in noise reduction, vibration and noise, especially suitable for the needs of urban construction. The hydraulic hammer pile driver has obvious effect and is the mainstream of the future development of pile drivers.

Hydraulic hammer is a fully hydraulic driven mechatronic product, which is easy to realize automatic control and monitoring of the working process. Therefore, the working parameters (impact stroke, striking frequency) can be automatically adjusted according to the working object (pile structure and geological conditions), so as to realize the ideal striking process. The impact force and the bearing capacity of the pile can be monitored at any time to protect the pile body from damage and ensure that all the driven piles have approximately equal bearing capacity, thereby ensuring the construction quality.

The hydraulic impact hammer is a machine tool and equipment that relies on the internal hammer core to impact the anvil to transmit the impact force to the pile body and realize the penetration of the pile body. The hydraulic impact hammer has low energy consumption, less pollution, high efficiency and good construction adaptability. The hydraulic hammer of this method has a simple structure and clear modularization, which is convenient for maintenance and repair of each module.

The hydraulic hammer has a high specific energy capacity, and the hammer head can be completely sealed in the casing. Therefore, it is easy to develop to large-scale and super-large, and it has irreplaceable advantages for diving operations in heavy foundation engineering and underwater construction. With the rapid development of marine development engineering, submarine oil exploration engineering, large-scale port and deep-water wharf engineering, large-scale highway, railway bridge engineering, underground engineering and high-rise building engineering, the product development of hydraulic hammer has more important significance.

A pile driver that can work independently usually consists of three parts: a self-propelled chassis, a pile frame and a pile hammer. The self-propelled chassis is divided into crawler type and walking type according to the walking mode. Among them, the pile hammer can be divided into two categories: vibratory hammer and impact hammer. According to different working medium, impact hammer can be divided into drop hammer, steam hammer, air hammer, diesel hammer and hydraulic hammer. There are two types of hydraulic pile hammers: free fall impact type and accelerated fall impact type.

Advantages of hydraulic piling hammers over other piling hammers

1. Soft ground adaptability

The strike energy and strike frequency of the hydraulic hammer pile driver are not affected by the reaction force of the foundation. The operator controls the hydraulic pile hammer completely through the electronic program. The striking process can avoid the phenomenon of pile slipping, and can realize the action of heavy hammer and light strike, and the strike of hydraulic pile hammer. The efficiency is many times higher than that of diesel hammers, and it has the characteristics of high efficiency, large kinetic energy, low hammer speed and small hammering stress.

Whether the diesel hammer can operate continuously depends on the combustion and explosion process of diesel, and the realization of this process is based on the reaction force of the foundation passing through the pile to the hammer core. , The soft foundation construction often cannot work continuously and even the pile slip phenomenon occurs.

2. Urban work adaptability

The hydraulic piling hammer is equipped with a high-efficiency diesel engine or a motor-driven closed hammer body. The noise of the muffler can be lower than 75dB, which is less pollution-free and suitable for urban operations. Insufficient diesel combustion results in a large amount of smoke emission, and the fuel explosion noise is higher than 100dB, which is not suitable for urban operations.

3. Energy controllability and continuity

The hydraulic hammer program control is convenient and accurate for soft foundation, and the low-stroke state can achieve high-frequency continuous strike. Under the same geological conditions, the process of test piles can be replicated to realize the procedure of group pile operation.

Diesel hammers, especially low-stroke control, are difficult to control and soft foundations cannot achieve continuous strikes. It is impossible to realize group pile program operation.

4. Energy utilization

The energy utilization rate of the full hydraulic power drive technology is over 67%.

The emission of the under-combusted mixed gas at high temperature and high pressure of the diesel hammer leads to a large amount of energy loss. The energy utilization rate is only about 20%.

5. Strike efficiency

The striking efficiency of hydraulic hammer can reach 60%~85% when combined hammer head technology and pile pressing technology are applied.

The conversion of the rebound potential energy of the hammer head makes the striking efficiency of diesel hammers only 25% to 45%.

6. Adaptability of large-scale pile foundation projects

The quality of the hammer core can achieve strong adaptability for large-scale pile foundation projects of 100 tons or even larger. Especially the foundation construction of super high-rise buildings has strong adaptability.

Due to the serious problems of cooling, noise, pollution and control of the sledge hammer, the weight of the core of the diesel hammer generally does not exceed 16 tons. General adaptability.

The low adaptability of diesel hammers cannot be achieved, and hydraulic hammers have no problems at all, such as underwater piling operations, inclined and even horizontal piling construction operations. The small hammer is equipped with a special pile cap and can have the function of pulling piles.

Advantages of hydraulic piling hammer

Strong controllability: The hammer stroke and hammering frequency can be adjusted at will, the output energy can be adjusted, and the action time of the hammer and the pile can be controlled, so as to avoid damage to the pile, optimize the operation efficiency and improve the productivity.

Reliability: The hydraulic hammer has a simple structure, an overall frame structure, low failure rate and easy maintenance.

Monitorability: The energy monitor directly and indirectly displays the working conditions, records the working parameters of the hydraulic hammer, and can save the records and input them into the computer and print the results.

Strong adaptability: It can be used for various construction methods and any pile type, which can be used on land or on water using a guide pile frame or a crane to hang it. It is especially suitable for driving vertical or inclined supporting piles.

Environmental protection: The hydraulic hammer operates cleanly, with low noise and no exhaust emissions.

Compared with diesel piling hammer, its advantages are: no pollution, meet the requirements of relevant laws and regulations, and are suitable for urban foundation construction with higher environmental quality requirements.

Compared with the static pile driver, the advantages of the hydraulic pile hammer are that it can be freely converted between three types of ordinary auger drilling rigs, rotary drilling rigs and diesel hammer frames, and it is convenient for transportation. In the reconstruction of the old city, there are many side piles, corner piles, and the advantages of hydraulic pile hammer for pile foundation construction in the vicinity of rivers or other obstacles.

No matter what kind of pile foundation construction equipment is used, it is better to choose the one suitable for the actual situation of the site.

Features of Hydraulic Piling Hammer

(1) According to the soil conditions and the strength of the pile material, the impact force can be reasonably selected to ensure the full play of the impact energy without damaging the pile body, and the pile pad can be omitted during construction.

(2) In the process of piling, the impact force and penetration index can be obtained at the same time, so whether the pile has entered the predetermined soil layer can be effectively determined.

(3) Characteristics of hydraulic hammer: It is suitable for inclined pile operation and underwater pile foundation construction. The hydraulic pile hammer does not have the problem of difficulty in starting soft soil, and it is suitable for construction operations in various climates.

(4) The impact energy can be increased a lot.

(5) The public nuisance of the hydraulic pile hammer is small, basically there is no exhaust gas pollution, and the noise during impact is about 20dB lower than that of other pile hammers.

Hydraulic hammer construction has many advantages. Foreign comparative tests show that the energy transfer efficiency of hydraulic hammer is much higher than that of diesel hammer. The energy transfer efficiency of ordinary diesel hammer is about 30~40%, while that of hydraulic hammer can reach 60~80%. The noise of hydraulic hammer construction is also much lower than that of diesel hammer. The noise of hydraulic hammer when driving piles is 80-85 decibels, while the noise of diesel hammer is more than 100 decibels. Hydraulic hammer has no oil fume pollution, meets environmental protection requirements, stroke stroke and frequency can be easily adjusted, and does not have the disadvantage of difficult starting on soft ground. Hydraulic hammer has a wider angle and greater penetration than diesel hammer. Adding a sealing cover can also be used for underwater piling and so on.

Construction method and scope of use of hydraulic piling hammer

1. Use with supporting pile frame. According to the type and size of the piling hammer, select the appropriate pile frame, including crawler pile frame, walking pile frame and suspended pile frame converted from crawler crane. The hydraulic piling hammer slides on the guide rail of the pile frame, and its landing gear is connected with the wire rope hoisted by the pile frame, which can carry out the construction of straight piles and inclined piles.

2. Supporting crane for hoisting construction. The hydraulic piling hammer is suspended by the wire rope of the crane for construction.

3. Use with piling boat. For the pile foundation of water buildings, due to the construction in water, it is generally used in conjunction with a piling ship, and the hydraulic piling hammer is guided and driven on the piling frame of the piling ship.

Hydraulic piling hammer has the characteristics of good controllability, wide adaptability, high striking efficiency, low pollution and low noise. In pile foundation construction, prefabricated piles are more and more widely used, and environmental protection requirements are constantly improving, and more and more large-scale projects have been put into construction, especially marine projects (such as offshore wind power, offshore oil, cross-sea bridges, deep-water wharves, etc. The large-scale construction of ) makes the precast piles develop in a larger and deeper direction. These factors have created favorable conditions for the application of hydraulic piling hammers. For different projects and under different conditions, combining theory and construction experience with the correct selection of the appropriate type of hydraulic piling hammer will greatly improve the construction efficiency.

The construction objects of hydraulic piling hammer are mainly prefabricated piles, including prefabricated reinforced concrete piles, steel pipe piles, H-beams, etc. Precast reinforced concrete piles are the most widely used in construction foundation engineering, including industrial plants, high-rise buildings and large bridges. Steel pipe piles are mainly used in basic construction such as large factories, high-rise buildings, deep-water wharves and offshore wind power. The H-beam is rolled by the factory and is suitable for soft soil layers. In addition to being used as a building foundation, it can also be used as a column pile supported by a foundation pit. Hydraulic piling hammers are widely used in these construction fields.

- Hengda Machinery Co., Ltd

hydraulic impact hammer - Hydraulic Impact Piling Hammer - hydraulic pile driver impact hammer